9 Things to Look for When Buying a Used Forklift

Sometimes you just can’t convince yourself to spend the extra money on a new forklift — even if it is a lease.

Or you have low hours of operation per week and cannot justify spending more money on something that you are only going to be using 20 hours per week.

If either of these is the case, shift your sights over to the used forklift market to save a little money. Or maybe — after reading this, a lot of money.

Below is a list of steps I have created to help make your used forklift search a breeze. Click on an option to jump to that section.

- Check the Forks For Damage

- Look for Gaps in the Lift Chains

- Watch How Smoothly the Mast Operates

- Look at the Tires

- Determine the Life Left in the Battery

- See What Shape the Engine is in

- Look for Leaks

- Make Sure the Safety Features Work

- Verify the Odometer Reading

Where to Shop for a Used Forklift

Look local!

Before you do anything, look within your area for forklift dealers.

Every material handling company will charge freight for delivering equipment to you.

Like any large purchase — besides you Amazon — you will be charged for the gas and time it takes to deliver the forklift to you.

So in order to save some on costs, check your areas first.

This can be as simple as going on google and typing in, forklift dealers near me.

Look at dealer websites and even check out some auction boards.

Just keep in mind that auctions are much higher risks because there is less information on the equipment background and you won’t know how well it was taken care of or what application it was used in.

A reputable used forklift seller will have certifications and safety regulations passed and will even offer a 30-day warranty with options that include both the powertrain and the parts and labor.

View our Used Forklift Fleet

What to Look for When Buying a Used Forklift

Knowing when to buy a used forklift is easy, but figuring out how to inspect a forklift can be tough, especially if you have little knowledge of the components that drive most of your ownership costs and maintenance.

These tips will give you some guidance to make a good choice.

1. Check the Forks For Damage

When inspecting a forklift you’ll most likely start in the front. Look for cracks, bends or any other signs of wear.

Cracks will be the most worrisome because they are early signs that your forks will need to be replaced soon.

A spot that is sometimes forgotten about is the heel of the fork blade. Look closely at the thickness.

If the back of the blade does not match the thickness of the upright fork shank (the part of the fork connected to the carriage) then your forks are worn.

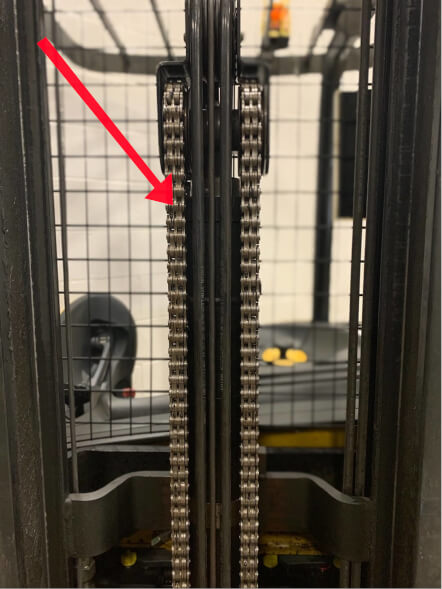

2. Look for Gaps in the Lift Chains

While moving your way up from the forks, look along the mast for any cracks or welding marks where cracks were fixed.

A poor weld will affect the structural integrity of the mast.

When looking in the middle of the mast you should view the lift chains for any missing or corroded links/pins.

3. Watch How Smoothly the Mast Operates

Have the dealer/seller raise the forks high enough to extend a second or third mast.

Any signs of a hiccup in the process means that either the link chain needs some fixing, the mast rollers are worn or the mast rollers have not been lubricated/well-maintained.

If the mast rollers are worn they will be a lopsided shape (more oval) and not a perfectly round wheel.

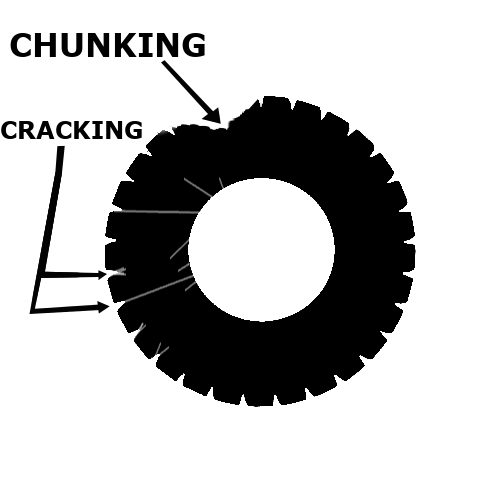

4. Look at the Tires

Get down and feel/look for any signs of chunking.

This look like a bite was taken out of the tire, below is a picture for your reference.

Another tell-tale sign that the tires are in rough shape is when the tread is low or non-existent.

The first area to look at is the wear line or the safety-line.

If the tire is worn past this line or is close to it then the tires will need to be replaced.

If there isn’t a wear line, look at the lettering on the sidewall of the tire.

Once the top of the lettering is reached the tire should be replaced.

Another test that can be very useful is the penny test! All you do is place Abe Lincoln in the tire groove and if the top of his head is visible then your tire tread is low, click here to learn more about this.

5. Determine the Life Left in the Battery

Unfortunately the number of hours on the battery is not tracked.

However, one quick check is to ask the dealer how many shifts the operation it was used in was and for how many years.

A normal battery will last about 5 years in a single-shift operations.

Therefore, if the battery was in a double-shift and is a year old. Then it’s got about 2-3 years left.

Another thing to check is exterior acid corrosion (only for lead-acid batteries).

Want to Learn More About Forklift Batteries?

6. See What Shape the Engine is in

After you run the forklift for a few minutes, open the engine compartment and look for leaks and any cracks on the hoses.

Pull out the dipstick to check the engine oil, low oil might suggest that there is a leak.

Make sure the belts are tight and well lubricated.

check brakes and transmission fluid

7. Look for Leaks

Places to check:

Mast cylinders and along the mast.

The transmission.

Around the radiator.

Emissions — check by smelling the air when the forklift is running. If you can smell high levels of carbon dioxide (on diesel engines) then there is probably a problem with the catalytic converter or the regulator.

8. Make Sure the Safety Features Work

The common areas you want to test are all geared towards keeping the operator safe.

Make sure the horn, seatbelt, seat adjustments, lights, brakes and levers all function properly.

Bonus: OHSA requires that overhead guards have damage less than 3/4″ deflection.

Look at the overhead guard frame, if there is any damage to it then your operator’s safety will be in jeopardy.

9. Verify the Odometer Reading

Before you do anything, make sure the forklift odometer has not been reset.

The easiest way to check this is to look at the body and amount of wear on major parts — if they don’t align with the hour reading then it most likely was reset.

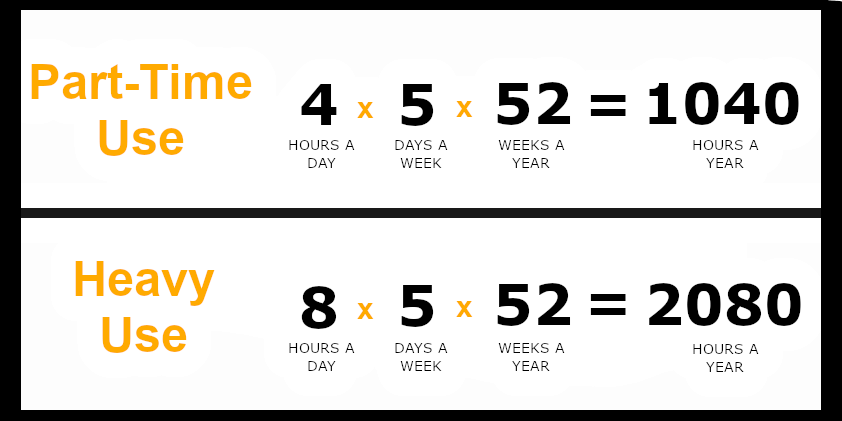

When looking for used equipment, part-time use is the best option.

But how do you figure this out?

While everything up to this point has been aimed at inspecting the parts and major cost-centered pieces of a forklift, the hours will give you the most insight into how long you can expect a used forklift to hold up.

For example, if you are looking at a 7-year-old reach truck that has 5,200 hours on it then you should expect the equipment to last awhile.

Now — you cannot base everything solely on hours, you still have to look at the other 8 areas listed above because maybe the tires were never replaced or maybe there are some leaks.

But, if the equipment averages over 2,000 hours per year then it will have more wear and tear and should be an early sign that you should walk away unless significant repairs and aftermarket parts were added.

Conclusion

There are many things to look for when buying a used forklift.

But, the most important elements that will save you thousands in repairs and cost of ownership down the line are:

- Buy your equipment from a certified used dealer (NOT online auctions, Craigslist, eBay, etc.).

- Purchase locally to avoid expensive freight costs.

- Inspect the age of the battery, an old battery that might need to be replaced will cost $1,500-5000.

- Bring a technician with you to look at the mechanical functionality.

- Check the odometer and make sure the equipment was used part-time.

Want Further Reading? Learn About the 5 Forklift Types Here

How many hours should a forklift last?

A forklift will last about 10,000 to 12,000 hours. If it is well maintained and serviced on time then some of the more reliable brands like Yale, Hyster and Crown will last 20,000 hours +.

How often should you change forklift oil?

Every 200 hours you should change the fuel filter, air filter, oil filter, and change the oil. After 500 hours you should change the hydraulic oil.

I’m glad that you mention having the forklift inspected by a technician to be sure that its functionality is good and to check for other things, such as the battery’s age. My cousin wants to start a construction business so that he’s more in charge of what projects he works on. Since buying a used forklift could save him money, I’ll have to tell him to get a technician to help him inspect them. This would also be useful so that he will have a professional that he can hire for any forklift repair services he might need later on in order to keep his equipment in good condition.

I’m glad you enjoyed the article! That is always a good call, best of luck to you and your cousin! Thanks for taking the time to drop a comment 🙂

Thanks for the tip that checking the life left in the battery is a good practice to have when buying a used electric forklift. Having to buy a new battery can be a surprising expense that I’m not prepared for. I’m going to need a forklift for transporting items around my farm’s warehouse so I’d appreciate it if I can buy one that doesn’t need any repairs or maintenance before I could start using it to start reorganizing the place.

You are quite welcome! I’m happy you were able to take some points away from reading the article. It’s always best to look only at dealers when shopping for aftermarket equipment because they have to go through OHSA approved inspections and will even throw in warranties.

The growing adoption of industrial automation solutions across various end-use industries is one of the major factors driving the growth of the global material handling market.